Masterbatch Silikon Berbasis PA ngirangan koefisien gesekan sareng ningkatkeun résistansi maké

Masterbatch Silikon Berbasis PA ngirangan koefisien gesekan sareng ningkatkeun résistansi maké,

sareng ngirangan waktos siklus, ngeusian kapang anu langkung saé, permukaan anu langkung saé, ngaleupaskeun kapang langkung gampang, rarasaan leungeun, Aliran lebur anu langkung saé, Ningkatkeun résistansi goresan sareng ngagem, konsumsi énergi anu langkung sakedik, Koefisien gesekan anu langkung handap, torsi extruder anu langkung handap, Masterbatch silikon dumasar PA, tekanan die ngurangan & die ngiler,

Pedaran

Masterbatch Silikon (Siloxane Masterbatch) LYSI-307 nyaéta formulasi pelletized kalayan 50% polimér siloxane beurat molekul ultra luhur anu dispersed dina Poliamida-6 (PA6). Ieu loba dipaké salaku aditif pamrosésan anu efisien dina sistem résin anu cocog sareng PA pikeun ningkatkeun sipat pamrosésan sareng ngarobih kualitas permukaan.

Bandingkeun sareng aditif Silikon / Siloksana konvensional anu beurat molekulna langkung handap, sapertos minyak Silikon, cairan silikon atanapi polimér silikon anu sanés, séri SILIKE Silicone Masterbatch LYSI dipiharep bakal masihan kauntungan anu langkung saé, contona,. Kirang selip sekrup, ningkat pelepasan kapang, ngirangan ciduh cetakan, koefisien gesekan anu langkung handap, kirang masalah cet sareng percetakan, sareng rupa-rupa kamampuan kinerja anu langkung lega.

Parameter Dasar

| Kelas | LYSI-307 |

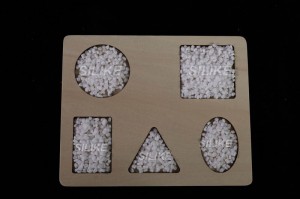

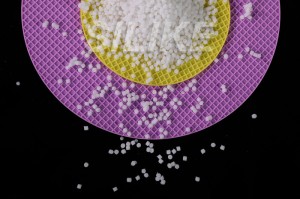

| Penampilan | Pelet bodas |

| Eusi silikon (%) | 50 |

| Dasar résin | PA6 |

| Indéks lebur (230℃, 2.16KG) g/10 menit | 36.0 (nilai has) |

| Dosis % (w/w) | 0.5~5 |

Mangpaat

(1) Ningkatkeun sipat pamrosésan kalebet kamampuan aliran anu langkung saé, ngirangan drool die ékstrusi, torsi extruder anu langkung sakedik, ngeusian & ngaleupaskeun cetakan anu langkung saé

(2) Ningkatkeun kualitas permukaan sapertos slip permukaan, Koefisien gesekan anu langkung handap.

(3) Résistansi abrasi & goresan anu langkung ageung

(4) Throughput anu langkung gancang, ngirangan tingkat cacad produk.

(5) Ningkatkeun stabilitas dibandingkeun sareng alat bantu atanapi pelumas pamrosésan tradisional

Aplikasi

(1) Sanyawa PA6, PA66

(2) Senyawa PA serat gelas

(3) Plastik rékayasa

(4) Sistem anu cocog sareng PA anu sanés

Kumaha cara ngagunakeunana

Masterbatch silikon séri SILIKE LYSI tiasa diprosés ku cara anu sami sareng pamawa résin anu janten dasarna. Ieu tiasa dianggo dina prosés campuran lebur klasik sapertos ékstruder sekrup Tunggal / Kembar, cetakan injeksi. Campuran fisik sareng pelet polimér murni disarankeun. Pikeun hasil anu langkung saé, pangeringan sateuacanna disarankeun salami 3 ~ 4 jam dina suhu 80 ~ 90 ℃.

Dosis anu disarankeun

Nalika ditambahkeun kana PA atanapi termoplastik anu sami dina 0,2 dugi ka 1%, pamrosésan sareng aliran résin anu langkung saé diarepkeun, kalebet ngeusian kapang anu langkung saé, torsi extruder anu langkung sakedik, pelumas internal, pelepasan kapang sareng throughput anu langkung gancang; Dina tingkat tambahan anu langkung luhur, 2 ~ 5%, sipat permukaan anu langkung saé diarepkeun, kalebet pelumasan, slip, koefisien gesekan anu langkung handap sareng résistansi mar/goresan sareng abrasi anu langkung ageung.

Pakét

25Kg / kantong, kantong kertas karajinan

Panyimpenan

Diangkut salaku bahan kimia anu henteu bahaya. Simpen di tempat anu tiis sareng ventilasina saé.

Umur simpan

Ciri aslina tetep utuh salami 24 bulan ti tanggal produksi, upami disimpen dina panyimpenan anu disarankeun.

Chengdu Silike Technology Co., Ltd is a manufacturer and supplier of silicone material, who has dedicated to R&D of the combination of Silicone with thermoplastics for 20+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnSilike silicone masterbatch LYSI-307, PA Based Silicone Masterbatch, used as an efficient agent in PA resins and glass fiber-reinforced PA compounds, significantly reduced the coefficient of friction and improved wear resistance at lower loadings than PTFE while retaining important mechanical properties. It also additives in processing efficiency and improves material injectability. Besides, helps finished components deliver scratch resistance while enhancing surface quality. In contrast to PTFE, silicone additive avoids the use of fluorine, a potential medium- and long-term toxicity concern. as well as silicone additive comes with doing something environmentally sound.

ADITIF SILIKON GRATIS JEUNG CONTO Si-TPV LEBIH TI 100 KELAS

Jenis sampel

$0

- 50+

Masterbatch Silikon kelas

- 10+

Bubuk Silikon kelas

- 10+

kelas Masterbatch Anti-gores

- 10+

kelas Masterbatch Anti-abrasi

- 10+

kelas Si-TPV

- 8+

Lilin Silikon kelas

-

Telepon

-

Surélék

-

Whatsapp

Whatsapp

-

Luhur

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur